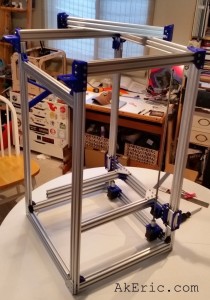

Building the C-Bot 3D printer: Part 10 : Assembly Day 3 & 4

Jump to C-Bot blog index to see all the posts.

I spent around six hours over two days knocking out the cantilevered build platform and addressing other ‘gotchas’ from previous days:

- I had totally forgot about the endstops when building the frame: Since Mason had created his own endstop solution, I ended up having to take a section of it apart and load up the t-nuts for the Z endstop. When I’m done with the build I’ll show where all the endstops ended up.

Today’s progress: cantilevered build platform, dual lead-screws installed, all endstops mounted. It’s starting to look like a real printer…

Why did it take so dang long just to add the build platform?

- I had ordered 8x 40mm spacers that help build part of the built-platform wheel assembly. But, Mason had failed to notify me they needed cut down to 25mm (it’s all good Mason <wink>). After much confusion and trying to fit parts together I txt’d him and learned this. So, it was down to the workshop with my saws-all and files to get some perfectly spec’d 25mm spacers:

- Once those were to the correct length, I could put together the wheel assembly. The order is: 55mm low-profile screw, 25mm spacer (cut down from 40mm), wheel shim, wheel, wheel shim, 1/4″ spacer.

- And with the help of my son holding it all in place, bolted it to the rear z-extrusions.

Other gotcha’s from today:

- After I got the build-platform mounted to the z-rails, the flexible couplings on the Z steppers wouldn’t mate properly with the lead-screws: A good 5mm off. I couldn’t find anyway to shim the printed parts, or see where anything was off: It all looked correct, but wasn’t lining up. So I ended up adding washers on top of the rear of both steppers to tip them “back”, and line them up with the leadscrews. This isn’t ideal (since now there is a slight angle between stepper and screw), but for now it will have to do (and is later fixed).

- When bolting the ACME lead-screw blocks through their printed holder into the extrusion (the black bolt-heads you can just make out in the top-middle of the above image), I didn’t have a bolt the correct length: I had to cut four of the M5x40mm’s down to 30mm so they wouldn’t hit the extrusion.

- From the image of the wheels above: When they bolted into the build platform, the bolts don’t stick all the way though the 3d printed parts so a nut can go on the end: And, two bolts on each side don’t seem to actually grip the 3d-printed holes at all, since the holes are slightly oval. I feel like if the bolts were 60mm, rather than 55, nuts could be put on the end and this would be a much sturdier assembly.

Jump to C-Bot blog index to see all the posts.