I purchased my Makerbot Replicator (1) when they were first released, nearly 3 years ago now. Other than a few hiccups (HBP cable failing repeatedly, and a dead botstep needing replaced) it’s ran like a champ. Reading the forums like I do, I’ve seen a number of people talk about their voltage regulators dying (the LM1084), and killing the whole board in the process. I don’t know when I’m going to upgrade, and I’d like to keep this machine running as long as possible, so an update was in order.

Makerbot users are always a super-helpful bunch, and the folks over at the Makerbot Users Google Group are no exception. I’d seen a lot of posts on the subject, but none that really broke down specifically what needed to be done, and what parts needed to be sourced. So I asked, and they answered. Armed with that knowledge (and this great photoset by JetGuy) I ordered from Digikey a “Recom Power R-78E5.0-0.5” voltage regulator (the 5v version, not 3.3v) based on user tramalot’s recommendation. Below are the overall steps I took to install it. It’s not hard once you grasp what needs done, and my hope is this breakdown can help others in the same situation.

First I sketched out the old and new wiring on paper: The new regulator has a different pinout: Everything has been shifted one pin left.

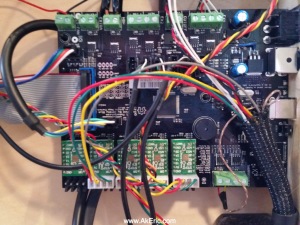

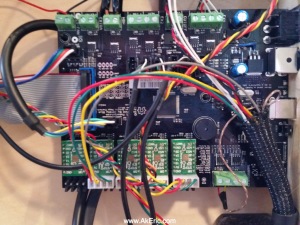

Next I snapped a pic of the Mightyboard pre-removal as a sanity check:

I made sure to ground myself with a wrist-strap just to be safe.

I then labeled all the wires with little stickies, unhooked everything…

(note, this is actually the board on reinstall, but it’s all the same)

(note, this is actually the board on reinstall, but it’s all the same)

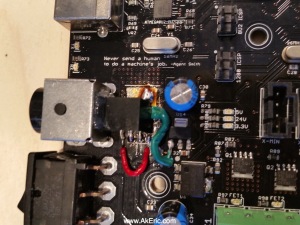

…and removed the board. Here’s a shot of the bare board, and the new voltage regulator:

Like discussed in the forums, I used snips to cut the leads from the old voltage regulator. I then took my soldering iron (the big, red, hand-held kind), and pressing it against the back of the reg, waited for it to desolder from the Mightyboard. I lightly twisted the reg back and forth with a pair of pliers at the same time since I had no idea if just the pressure from the iron would move it. It took a lot longer than I expected, and at one point I thought it wouldn’t work at all. I’m guessing I had to hold it from 5+ minutes.

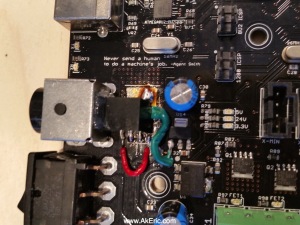

From there I desoldered the old remaining leads, and soldered in the new voltage regulator using wires to aid in the pintout offset. I liked what JetGuy had done in his Flickr post, so I hot-glued it to the power receptacle for extra stability:

(Note the brown/orange cruft is just left-over flux)

(Note the brown/orange cruft is just left-over flux)

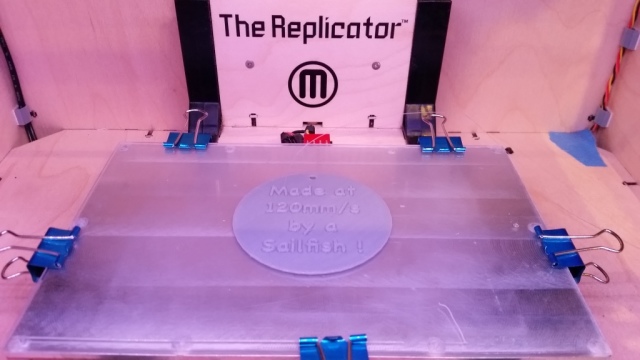

Put it all back together, and I was relieved when it turned on, and printed successfully.

I figured while I had it apart I should provide for some extra cooling, so I drilled out a 1.5″ hole right by the Mightyboard fan. However, after I did this I had more conversation on the above forum linked above, and learned that the Mightyboard really needs no fan cooling at all. But… having it there should’t hurt.

Hope this gives my rep1 many more years of good printing

My thanks again goes out to the Makerbot Users Google Group users JetGuy, tramalot, and Joseph Chiu for their helpful advice!

I’d done a few experiments in the past with the Kinect / Skanect software (here, here). The biggest issue (other than my underpowered Macbook Air) was that you’re tied via the USB cables to both the computer, and the electrical socket in the wall: Hard to walk around things to scan them.

I’d done a few experiments in the past with the Kinect / Skanect software (here, here). The biggest issue (other than my underpowered Macbook Air) was that you’re tied via the USB cables to both the computer, and the electrical socket in the wall: Hard to walk around things to scan them.