Building the C-Bot 3d Printer : Part 39 : Magnetic, removable build plate

Jump to C-Bot blog index to see all the posts.

Back in Part 33 I’d added a nice, perfectly flat mic6 aluminum tooling plate as my bed. And as a super flat surface, it’s been great. Later, I added a piece of PEI to the top which in general, is a great surface to print on.

The issue, is that I have an inductive probe. And these probes are designed to detect ferrous metals, like steel, not aluminum. Because of that, with the PEI sheet on top, the probe was nearly 1mm from the top of the sheet. Which caused various print failures over time, when some bit of plastic would ‘wick up’ while being printed, harden that way, and the probe would catch it.

Based on a recommendation, a buddy of mine recently picked up a Prusa i3 MK3 (which, for the price, is an amazing printer), that has a super slick removable flex-steel bed, with PEI (I think) impregnated on the top. And since it uses an inductive sensor as well, the steel plate is the perfect thing to detect against.

After doing research onling, I found that BuildTak sells upgrade kits (‘Flexplate’) in various sizes that do this: I thought this would be a good route to go, until I saw the price: My 12″x12″ bed would run $170 for the kit.

After thinking about it a bit, I realized this isn’t a complex problem to solve: All you need is a piece of thin, flat steel, and a magnet to hold it down. And what if that magnet was flat as well, with sticky on one side to hold it to my aluminum bed? After some searching on Amazon, I found these:

- Flexible Magnet Sheet With Adhesive : 12″x24″, $9.40

- Online Metal Supply 1008 Cold Rolled Steel Sheet (22 ga.) .029″ x 12″ x 12″ : $12.60

- Total: $22

It showed up in the mail in only a few days: I cut the magnetic sheet in half for a nice 12″x12″ chunk, and stuck that directly to my aluminum bed.

I took my orbital sander with some 100 grit to the steel sheet to roughen it up.

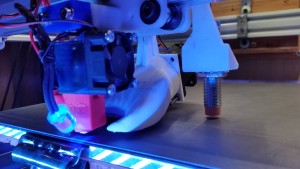

The steel sheet firmly magnetized itself in place, and I tuned my firmware for the new sensor offsets, and got to printing:

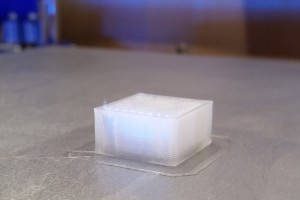

Just steel, and purple gluestick: Perfect.

Update: A few things to note since first posting:

- What I bought wasn’t ‘spring steel’ : While you have to put some effort into it, you can bend this metal to be non-flat. Must be careful. Or, buy spring steel. I was aware of this ahead of time, this was mainly a test.

- I print mostly in PLA, and the magnet & adhesive have done fine at 60c. However, I have no idea how well that magnet or adhesive would do at say, 110c printing ABS. Be aware of that if it’s your setup.

- If this (magnets + adhesive + heat) becomes an issue, I plan to CNC some pockets into my bed, and drop in some strong magnets. I’ve read that for high-temp applications, you want to go with ‘Samarium–cobalt (SmCo) magnets’.

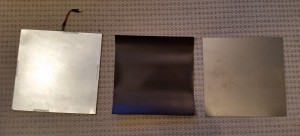

From left to right: Aluminum plate, flexible magnet, steel sheet:

Here, you can see the stack of aluminum build plate, magnet, and steel sheet. The gap between the sensor and sheet is actually larger than that, I’d not set it’s height yet.

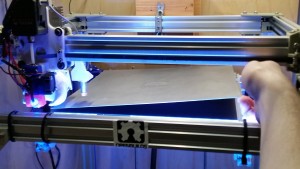

Here’s showing off a little bit of flex:

And finally, a successfully printed 200 micron calibration cube directly on the steel + purple gluestick:

And while it looks like there was a little bit of bed separation on that front corner, that thing was stuck down hard.

Great, cheap, easy improvement!

Jump to C-Bot blog index to see all the posts.