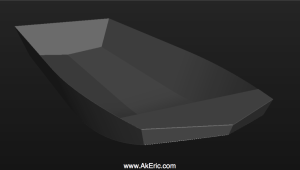

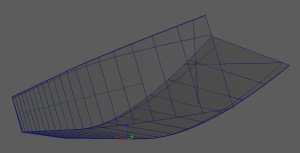

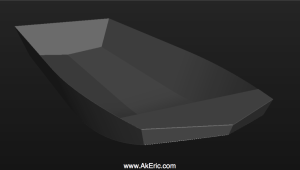

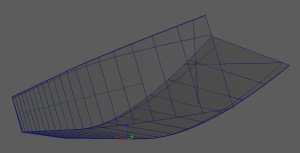

Maya render of the boat

Current state of the boat, with my father and brother.

My father has been building boats since before I was born and running them on the rivers of Alaska: Fiberglass canoe? Check. Flat-bottom wooden riverboats with dual outboards? Check. Should I mention the hovercraft? 😉 Over the past decade he’s branched out into welded aluminum flat-bottom riverboats with great success: Make one, use it for a few years, sell it and make an upgraded version. (On a side note, I can’t wait to retire… <wink>)

Late last year he came to me wondering if I could help with the design: Could I create the 2d design files he would provide to a local plasma-cutter to cut the main boat forms? Sounded like a good challenge, and a great opportunity to collaborate with my father (He’s in AK, I’m in CA). Up until then he’d get the huge sheets of aluminum and cut them by hand. Having a plasma-shooting robot do that sounded like a more exciting (+ accurate/faster) solution.

My father provided me the drawn plans with angles and dimensions: I started the process of turning those into real 3d forms.

Initially I attempted to do the whole project in Autodesk Fusion 360: I’d been teaching it to myself, but I was still very much a noob in the software. Unfortunately I just couldn’t get it to do what I wanted: Most importantly I couldn’t ‘unroll’ the 3d forms to 2d forms, which is needed for plasma cutting. I worked directly with their support on this, but the software just wasn’t quite there yet.

So I decided to do it all in Autodesk Maya (which I’ve been using since it was released in ’99). While Maya is great for games\film\vfx, I’d never much considered it for accurate CAD-style modeling. However, it ended up working great. Here are the main takeaways on how I built the boat:

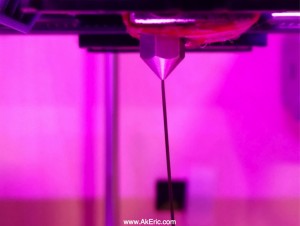

The initial boat model:

- I started by modeling the real-world size sheets of aluminum out of NURBS planes.

- I snapped and rotated the pieces together to get the overall shape of the boat based on the provided angles.

- I applied bend deformers on a single axis to shape the NURBS into the correct swept forms.

- Based on all the intersecting NURBS, I created curve-on-surface intersections:

Right side bent NURBS intersection, with curves-on-surface, before trim.

- Based on those intersections, I trimmed away the excess aluminum (NURBS).

- Boat model complete! (see above render)

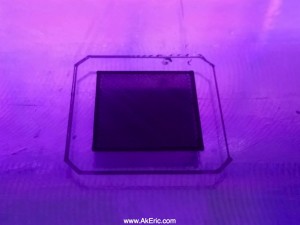

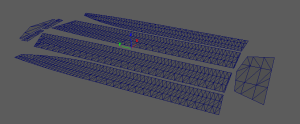

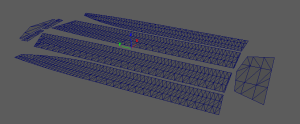

The unwrapped form:

- I needed to ‘unwrap’ all the bent surfaces back to flat planes for export.

- To do this, I would duplicate each of the bent/trimmed NURBS, convert them to polygonal mesh, and wrap deform the polys back to the original bent NURBS.

- On the original, I’d access the bend deformer, and zero it: This would flatten out the wrapped polys. I’d delete history on the polys, leaving it flat, then bend the original piece back. I’d then scale it perfectly flat, since the wrap wasn’t 100% accurate.

- I’d repeat that process on each bent piece, ultimately giving me unwrapped flat pieces for all parts of the boat:

Unrolled polys

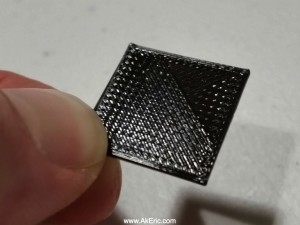

Exported 2d data:

- I exported each polygonal mesh as obj. I then used online software to convert the obj to pdf’s, which the plasma cutter could use.

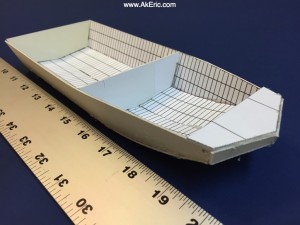

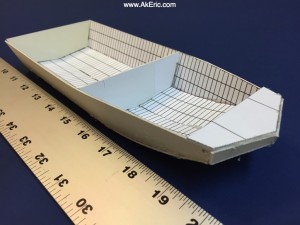

After my father got the 2d data he printed a scale model on paper, affixed it to poster-board, and made a small-scale mockup as a sanity check:

From there, it was off to the plasma cutter…

And the most amazing part? It all worked: After my father got the pieces back from the plasma cutter and starting tacking them, they all fit perfectly. Sighs of relief on all sides.

While it’s been fun to 3d print small items, it was super rewarding to see a much larger-scale 3d model become reality, and do some ‘real’ work with my father. I can’t wait to ride in it!

Update: See the final results here!