4WOC : Week 4

Onto my last week of creativity! Back to week 3…

Days 26-28, Thurs -> Sunday, December 2013

Well, the last three days were a bit of a creative fail, in a way: Thursday I was just exhausted after work, friday my best friend flew into town as a surprise for my… birthday party on Saturday. So while the last to days were very enjoyable, they weren’t necessarily ‘creative’. Unless you count a beer-tasting birthday party as creative

Day 25: Wednesday, December 4th, 2013

Almost printed…

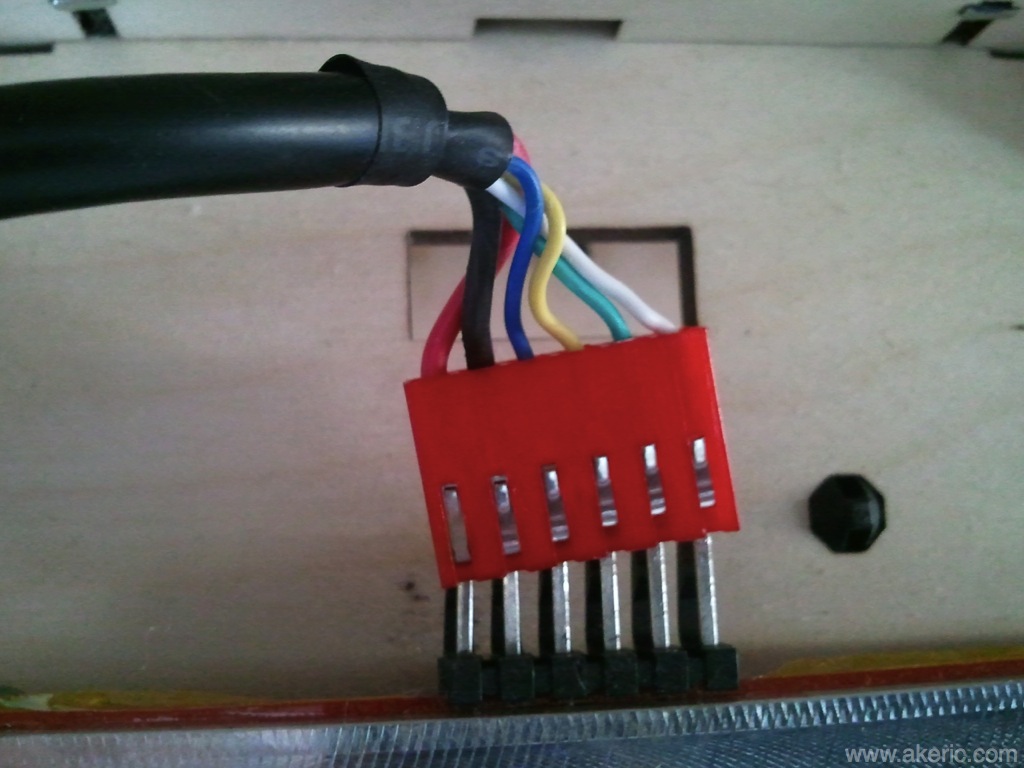

One minute shy of the ten hour mark, the below print finished (on my Makerbot Replicator 1). I should have known better though, and modeled in my own support columns for the overhanging clasps: As expected they broke free at some point during the print, and it failed. That being said I still cleaned it up and snapped a pic of it on my arm. I won’t re-print it: I don’t like it that much. But it was a fun exercise in the scan -> model -> print process I’d not tried before.

Day 24 : Tuesday, December 3th, 2013

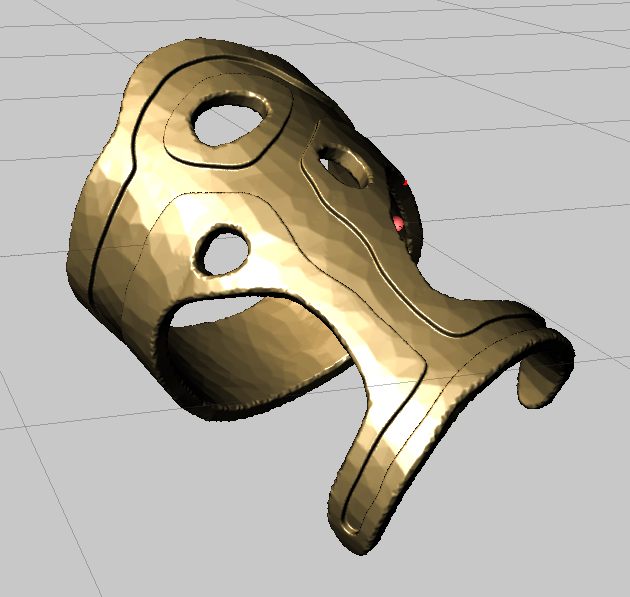

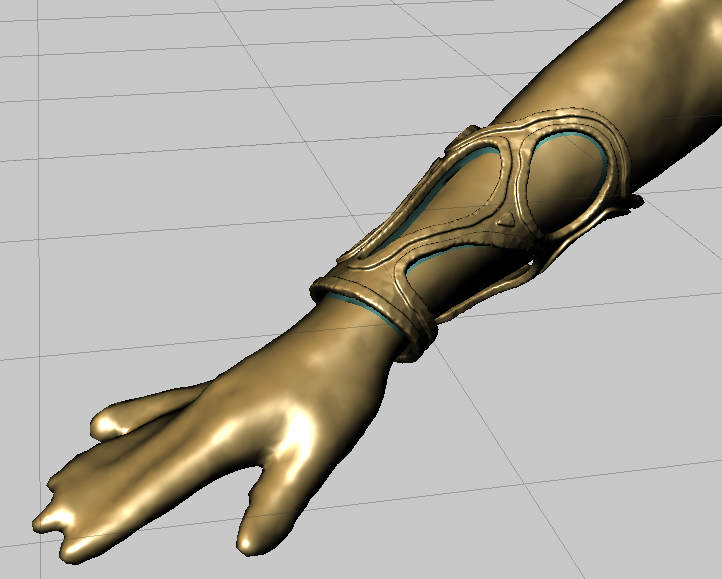

Moar Meshmixer

It dawned on me after finishing the sculpt yesterday: It would be impossible to actually get ones arm in that thing, based on the size of the wrist. Tonight, I did a new sculpt that should be far more… ergonomic, when it comes to wearing it:

Hopefully can start printing it tomorrow!

Day 22: Monday December 2nd, 2013

Meshmixing Skanect

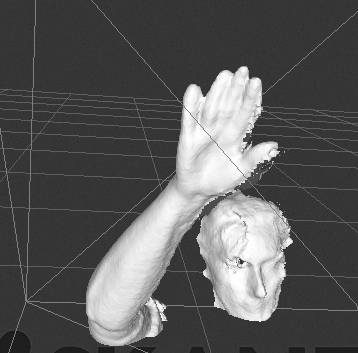

Over the weekend I’d bought a used Kinect, and had scanned my Makerbot Replicator as a test… although not a very useful test. During that process I learned that Skanect likes to crash pretty often on my Macbook Air. I figure I need more horsepower: I thought I may be able to get gpu acceleration working, but after checking the Skanect Google Group, I was told my grahics card (GeForce 320m, 256 meg) isn’t supported

Regardless I thought I’d try a more complex subject: My wife’s arm. I tried several times walking around her holding the scanner while she held her arm up, but I just couldn’t get a good scan. So I got her on a spinny-chair and had her spin in a circle: Success. However, I can’t get any scans to work on “high” quality: It just crashes at some point. But medium and low quality seem to work.

Here’s the result in Skanect, and later in Meshmixer: I imported the scanned mesh, smoothed it, and started drawing patters which I later extracted, extruded, and detailed. My hope is to get this mesh into Maya where I can split it in half for 3d printing.