Printing PLA with the Replicator

I’ve been printing in ABS since receiving my Replicator last year. Today I finally made the switch over to PLA. The ‘why’ is mainly to try something new… see how a new medium prints. But there are other benefits:

- PLA doesn’t need to have the HBP (heated build platform) heated to 110 deg Celsius like ABS does : I read it dosen’t need to be heated at all, but many people find success at around 40 deg C. What this means is the HBP heats a lot faster…. meaning things print faster.

- You don’t have to affix kapton tape to the HPB: ABS sticks really well to kapton tape, and that’s why it’s used. But it’s difficult and time consuming to get the tape applied to the HPB: PLA can print on ‘blue painters tape‘, which is much more forgiving when being applied to the HBP.

- PLA is biodegradable: More ‘green’ than ABS.

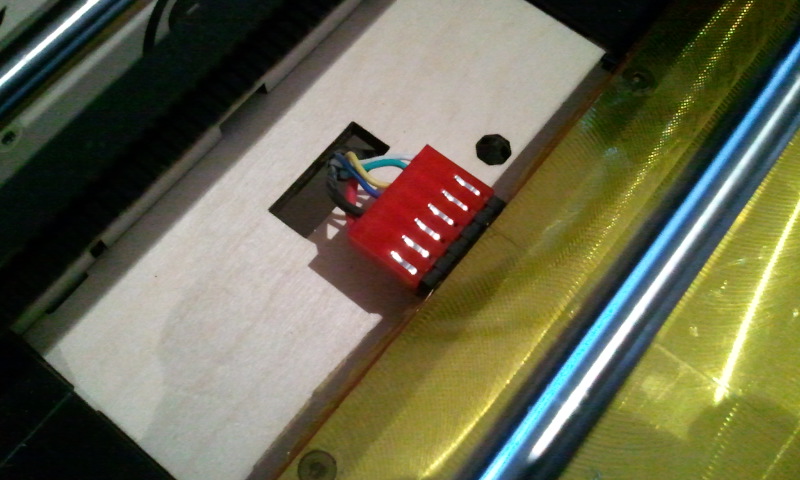

First test run successfull, pic below. Some notes on the process:

- Extruder temp set to 210 deg C.

- HBP temp set to 40 deg C.

- Purged the ABS by ‘loading’ the PLA for 5 minutes straight, per online docs.

- GCode compiled via ReplicatorG 0040, Replicator firmware 6.2.

- Used ‘natural’ colored PLA, it’s semi-transparent.

I’m still getting a ‘bug’ where when during the pre-heat, filament ‘leaks’ out of the extruder nozzle. On the ABS it would happen slowly, but with the PLA, I can physically see it leak out. The side effect is the ‘anchor’ it first builds on the corner of the HBP doesn’t always fully form… which can screw up the start of the printing session. But this first print tured out a-ok.