Building the C-Bot 3d Printer : Part 37 : 2017 Redux

Jump to C-Bot blog index to see all the posts.

Hard for me to believe I built the C-Bot just over two years ago. During that time I’ve done a number of upgrades, but a weird z-wobble had shown up in the process, that I’d been completely unable to resolve.

After discussion on the C-Bot/D-Bot 3D Printer Google Group, I generated a new list of parts to re-3d print, to improve my bot. So I really can’t call this a C-bot anymore, it’s more of a C-Bot/D-Bot/Spiffbot (+ others) mashup at this point.

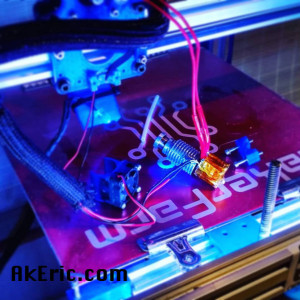

So after two weekends of disassembly & reassembly, the CDSO-bot is back up and running. Behold:

The colors are a bit like a time machine: Anything in blue is original prints. White was printed next, and latest is gray.

Overview of my updates below. Huge thanks to all of those who have put time in to improve these files, and release them for free!

- Printed all new lower corner brackets based on the Spiffbot designs. These add the bulk of the rigidity to the new system. Feels like a tank now.

- https://www.thingiverse.com/thing:1629139

- corner_bracket_1_2x.stl

- corner_bracket_2_2x.stl

- https://www.thingiverse.com/thing:1629139

- I remixed the D-bot top XY-idlers, extending them down on Z an extra 20mm, to provide for even more z-rigidity.

- https://www.thingiverse.com/thing:2394453

- Rear_Idler_Left_Long.stl

- Rear_Idler_Right_Long.stl

- https://www.thingiverse.com/thing:2394453

- Switched my X-endstop to now be on the X-carriage instead of the Y-gantry. Used the ‘X-endstop mount for the direct-drive gantry’, by pizzachef. This cleaned up a bunch of wiring from the left side. While it added more mass to the toolhead, it seems pretty negligible.

- https://www.thingiverse.com/thing:1898391

- X_endstop_mount.stl

- X_SwitchTriparm.stl

- https://www.thingiverse.com/thing:1898391

- From the D-Bot remix by spauda01, leadscrew brackets and bed supports:

- http://www.thingiverse.com/thing:1001065

- 2-Lead_Screw_Bracket.stl

- 4-Bed_Support.stl

- http://www.thingiverse.com/thing:1001065

- All new smaller, 3-wheel brackets for my Y Gantry, by BucketOchicken. These are nice in providing slightly more space on +/- Y.

- https://www.thingiverse.com/thing:1833099

- H-Bar_Left.stl

- http://www.thingiverse.com/thing:1833260

- H-Bar_Right.stl

- http://www.thingiverse.com/thing:1833072

- 3_Wheel_XY_Backer.stl

- https://www.thingiverse.com/thing:1833099

- Used some silicon caulk to affix a 12″ square chunk of cork under the heated bed. Hopefully will heat up faster, and save some energy.

- Switched from the front/back leadscrew design to the “middle, side-by-side design” (+ brass nuts), just to try something new, since I had the spare extrusion. The extrusion is held in place by triangular aluminum brackets, making the base even more rigid.

- The top front X-beam is now held in place my much stronger aluminum triangle-brackets.

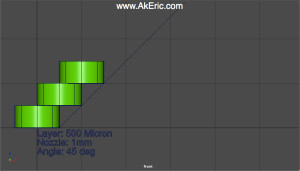

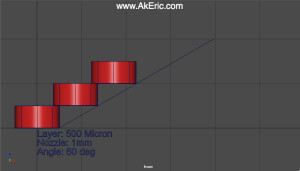

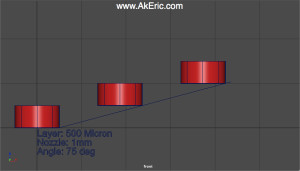

Here’s another pic of some of the updated parts I printed, mocked up to make a very tiny printer 😉

Successes:

- Once I rebuilt everything, and got all the electronics re-hooked-up, everything still worked! No magic smoke, nothing exploding.

- The dumb z-wobble I was experiencing is gone!

- Update: Wait, no it’s not. ARGH!

Issues:

- With the new L/R leadscrew config, they now hit both my “beefy print cooler fan” (on the left), and my inductive probe (on the right) if printing all the way to the edge of the volume: I’ll need to remove them, and cut about an 1″ off to solve that problem.

- I ran out of T-nuts: I had a surplus during my last build, but this one used up all the remaining ones, and then some. So waiting for that delivery slowed things down a bit.

- Even with the giant new base-corners, it still wasn’t square on top: While the based seemed to be nice and square, it took some time to get all the top extrusions back in line.

Overall, a very successful rebuild. Here’s to another two years of 3d printing!

Jump to C-Bot blog index to see all the posts.