Building the C-Bot 3D printer: Part 14 : Electronics Day 1

Jump to C-Bot blog index to see all the posts.

Update: Since authoring this post I have switched my electronics to RADDS, and my firmware to Repetier. See the “Part 31 post” for the latest on it.

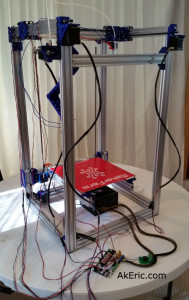

Today I mocked up the bulk of the electronics: Connecting wires, running cables, plugging them all into the Rumba. The only ones I wasn’t able to complete were the wires for the extruder heater block and the HPB themistor, since my soldering iron broke. I also wasn’t able to wire the the HPB relay fully, since I don’t have any extra 10awg wire laying around, that I’ll need to solder to the HPB leads. But other than that, all the electronics got wired and hooked up.

Total time: Around five hours.

Overall I:

- Went to the electronics store and got all sorts of various JST connectors and whatnot to get everything hooked up.

- Connected all wires to components, and into the Rumba (see gotchas below). My Rumba kit came with a bunch of wires, which made this pretty easy.

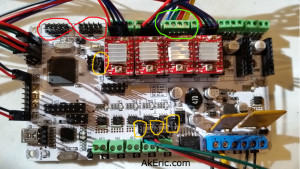

- Should call out that since I have two z-steppers, they both get slaved to the same stepper driver: They both plug into the same terminals. In the below image, this is circled in green.

- Hooked up the LCD screen (see gotcha below).

- Set the stepper drivers current limits (details below).

- Turned it on. Not much I can do since I need to update the firmware to recognize the Core-XY geometry. But at least it turns on and I can play with the menus

Still need to:

- Get some nice wire-wrap to cover all the bundles of wires.

- Get more 10awg wire to hook up the HPB.

- Find the final routing solution for all the wires.

- Finish up the HBP and thermistor wiring/soldering.

Notes from the day:

The Rumba hardware I bought on Ebay:

Docs:

- Geeetech Rumba.

- Pololu A4988 Motor Stepper Drivers that came with it (well, a knockoff).

- Youtube vid for ‘Setting the current limit‘.

- Reprap Wiki docs.

- Reprap Wiki Install Guide for the Chinese version I got.

- Reprap Wiki ‘Tuning Motor Current‘

Handy pics I printed:

I had these around me all the time, made it easier to figure out where things went.

Jumper Settings:

There are several jumpers that need to be set on the Rumba. My Rumba only came with one, but you need to set four total.

- Be sure to set the jumper (to the left of the left most stepper driver) to 12v power, not the 3.3v USB.

- Above the right three green mosfet terminals, there are jumpers: Set each of them on to bottom two pins, setting them to 12v power.

In the below image, the jumpers are circled in yellow:

Red = flipped silkscreen. Green = Double z-steppers. Yellow = Jumpers. Note the order of the stepper wires circled in green is wrong in this shot.

Tuning the stepper driver current limit:

(Note, I have since replaced these with DRV8825’s, check out this post to see a better way to tune them up).

The OpenBuilds Nema 17 steppers I purchased can draw 1.68A per phase, according to the web page. The A4988 Motor Stepper Drivers, from their page, list their ‘maximum current per phase’ at 2A: It’s higher than our steppers can draw, and that’s good

There appear to be a variety of ways of setting the current limit, but a way that Mason used is this : Using alligator clips, connect one lead from your multimeter to the ground pin on the A4988, and the other to a small screwdriver: You can then put the screwdriver in the trimpot and check the resistance : For the A4988, you want to set it to just under 2.5x what the stepper can draw (you can find this formula under the ‘Current Limiting’ section of the A4988 page linked to above). My stepper can draw 1.68A, that divided by 2.5 would be .672, or 672 ohm on my multimeter. Note, after going through all these steps, I learned that the value on the multimeter actually needs to 10x that amount: So I’ll got just a bit under, and set it to 6500 ohm. It should be noted that other stepper drivers have different values. For example, the DRV8825 (what Mason’s using) divides by 2, not 2.5.

There appear to be a variety of ways of setting the current limit, but a way that Mason used is this : Using alligator clips, connect one lead from your multimeter to the ground pin on the A4988, and the other to a small screwdriver: You can then put the screwdriver in the trimpot and check the resistance : For the A4988, you want to set it to just under 2.5x what the stepper can draw (you can find this formula under the ‘Current Limiting’ section of the A4988 page linked to above). My stepper can draw 1.68A, that divided by 2.5 would be .672, or 672 ohm on my multimeter. Note, after going through all these steps, I learned that the value on the multimeter actually needs to 10x that amount: So I’ll got just a bit under, and set it to 6500 ohm. It should be noted that other stepper drivers have different values. For example, the DRV8825 (what Mason’s using) divides by 2, not 2.5.

ALL THAT BEING SAID, none of it really mattered later, when I went to go dial in the settings manually (later post). So maybe it’s a good place to start, but ultimately doesn’t seem to matter.

VERY IMPORTANT: When you go to install the stepper drivers in the Rumba, be sure to insert the stepper drivers in with the trimpot “down”, or away from the capacitor beneath it. See my above image for reference. I found docs online describing this, and telling me to do the exact opposite (which would probably blow the drivers): As it turned out, this was for a RAMPS 1.4 board, rather than a Rumba 1.4 board. Close one!

Gotchas:

- So when I looked at the Nema-17 wiring harness, I realized that the order of the wires changed down the length of the harness. This is shown in the below image. So, I went through every single end terminal and swapped them out to the same as the other end, thinking this was correct. It is not, just leave it alone. I got to swap it all back again :S

- From this diagram, A/Green, A-/Yellow, B/Red. B-/Blue

- From the Rumba Board: 1B/Black, 1A/Green, 2A/Red, 2B/Blue

- But… comparing those two things makes absolutely no sense since both the colors and A/B descriptors differ. According to Mason he plugged his into the board in the order RBGY, and it works, so that’s what I’ll do.

- The silkscreen on the Rumba is wrong when it comes to the two smart-display ribbon cables: When I first turned it on, the LCD didn’t light up, and it just made a slow beeping sound. After doing some searching, I learned that the skilkscreen for that area on my Rumba was both reversed, and backwards. Meaning, I needed to plug the ‘exp1’ cable into ‘exp2’, and the ‘exp2’ cable into exp1. And, they both had to be rotated 180 degrees. Crazy! In the above image, this is circled in red.

- My soldering iron died. So sad.

Jump to C-Bot blog index to see all the posts.